Force Meter

A dynamometer is a measuring device in which an elastic body is deformed under the influence of a force.

Basic principle "Hooke's law"

The simplest and most well-known type of force gauge from physics lessons is a spring balance. Here, a spiral spring is extended as an elastic body by an acting force (F).

In the elastic range of this spring body, Hook's law applies, which describes that the quotient of the increase in force and the increase in length is constant.

With a spring scale, only the mass (M) is traditionally determined in the SI unit kilogram [kg]. In order to use a spring scale as a force gauge, however, the scale should always be in the SI unit Newton [N].

Mass and weight

Before 1960, force was measured in kiloponds or pounds force. After that, Newton [N] was defined internationally in the SI system of units.

Weight force [N] = mass [kg] x gravitational acceleration [m/s²]

The gravitational acceleration on earth is about 9.81 m/s². However, it varies depending on the distance to the poles and local geological influences. According to the formula above, a mass of 1 kg causes a weight force of approx. 9.81 N on earth, in a rough approximation. On the other hand, the same mass of 1 kg only causes a weight force of approx. 1.62 N on the moon, since the gravitational acceleration there is only 1.62 m/s².

If you want to determine the gravitational acceleration at your location as precisely as possible, the following link to a page of the PTB (Physikalisch-Technische Bundesanstalt), Braunschweig will help you

SIS | gravity information system

Why a spring scale can only be used as a force gauge under very limited conditions becomes clear when you look at the two essential basic properties of force.

Define power

Force as directed physical quantity

Force is defined as a directed physical quantity that plays an important role in classical mechanics. It can accelerate or deform bodies, through the effect of force one can do work and change the energy of a body. Physics distinguishes four basic forces:

- the gravity;

- the electromagnetic force;

- the weak nuclear force (interaction);

- the strong nuclear force.

Many forces have independent designations due to their causes or effects, e.g. friction force, weight force, centripetal force (centrifugal force), tensile force, closing force or opening force, holding force, muscular strength, etc.. The internationally used unit SI applies to all of them. Unit of force, the Newton [N] with the symbol = F (lat. fortitudo).

Only the weight force is defined with regard to the effective direction of gravity towards the center of the earth. However, the other basic forces can act in any direction. In practice, therefore, we always have to deal with a number of mutually influencing forces when measuring forces. A very simple example of this is a holding magnet on a board: only if the magnetic force is greater than the weight acting on the magnet due to its mass will the holding magnet not fall to the ground.

Force as a location-independent variable

While the weight caused by a mass can vary from place to place, the physical quantity of force measured in Newton [N] is location-independent.

For example, if you need 10 N to open a flap held with tension springs on earth, you also have to apply 10 N (muscular) force on the moon to open the flap. If you want to open the flap with weight (force) instead of muscle (force), you should take at least 6.2 kg (10 N/1.62 ms²) with you instead of 1 kg of mass.

Types of force gauges

Mechanical force gauge

The spring balance described above, as a simple mechanical dynamometer, has the disadvantage that a relatively large deformation (i.e. lengthening of the spiral spring) is required in order to achieve a sufficiently good scale resolution.

For example, a spring scale with an N display is approx. 100 mm longer with a measuring range of 10 N in order to achieve a scale resolution of 0.1 N. The measuring range of mechanical force gauges with a round analog scale is significantly shorter.

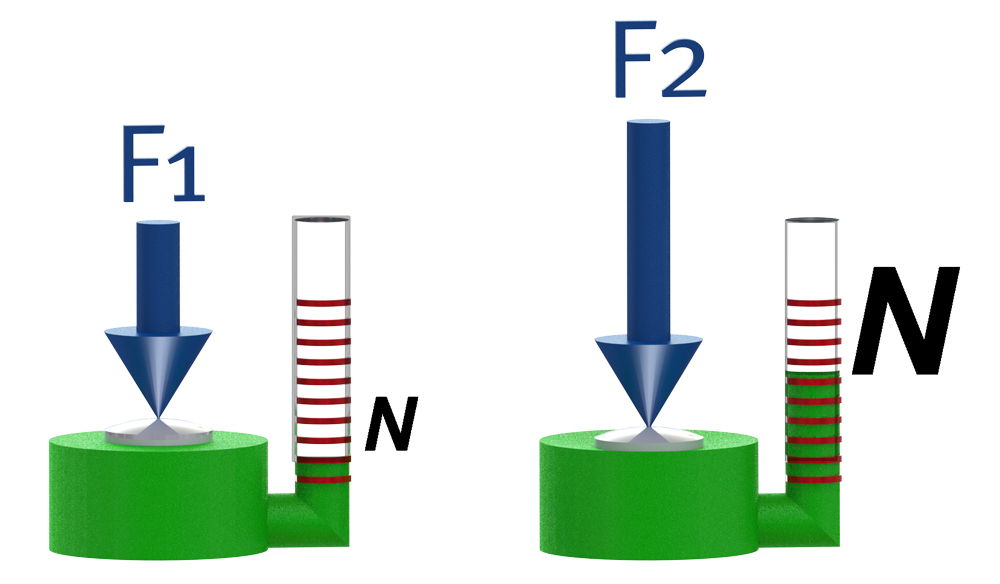

(Principle sketch: mechanical force gauge with round analogue display)

As with a dial gauge, the compression or elongation of a spiral spring is transferred to a pointer in order to increase the resolution at the expense of the measuring accuracy.

Hydraulic force gauge

The hydraulic force gauges are often referred to as load cells or pressure cells due to the typical round design with a hollow body and a separate force display.

In these liquid-filled measuring devices, too, a metal membrane is elastically deformed under the influence of the force. The resulting reduction in volume increases the pressure proportionately, or the volume is displaced.

(Principle sketch: hydraulic force gauge - load cell)

Force gauges that are constructed according to this principle can usually only measure in one effective direction and are mostly used to measure very high forces.

Modern digital force gauge

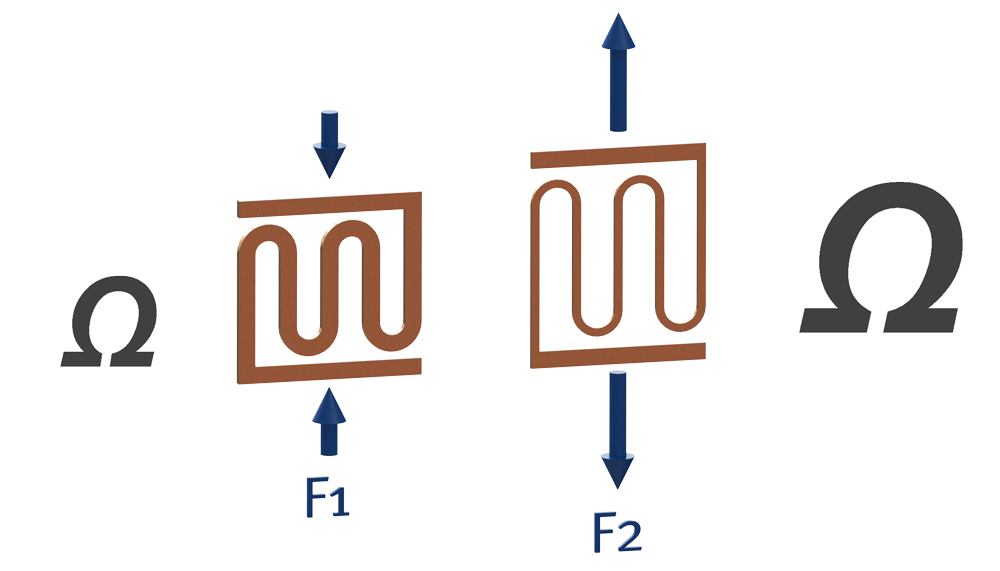

Today, digital force gauges are essentially based on sensors with DMS (strain gauges). The very slight elastic deformation of a sensor body is transferred to a measuring grid, as a result of which its line cross section is changed by the expansion and/or compression.

This change in cross-section causes a change in electrical resistance, which is evaluated in the measurement electronics. In principle, Hooke's law also applies here in a figurative sense, although the proportionality is established through the design measures on the force transducer and algorithms in the electronics.

(Principle sketch: strain gauges)

Essential for the quality of a digital force gauge is the exact matching of the sensor body to the evaluation electronics and the installation situation of the actual force transducer in the housing. Good digital force gauges are characterized by perpendicular and friction-free application of force, the lowest possible mass and high flexural rigidity at the same time.

Advantages of digital force gauges

The advantage of a digital dynamometer lies in the very small nominal measuring range of 0.1 to 0.3 mm, with high resolution and accuracy. Parasitic force influences from the introduction of force or the position of the force measuring device in space are significantly lower and it is therefore possible to achieve significantly better comparability and reproducibility of the measurement results.

With most digital force gauges, tensile and compressive forces are measured and the force is applied in the tensile and compressive directions on the same measuring shaft.