Force Gauge

A force gauge is a measuring instrument with direct indication of the SI unit Newton [N] with which a force is exerted or on which a force acts. For this purpose, the device is pressed as a hand-held force gauge onto the object under test or pulled away from the object or firmly fixed like a force transducer in a test stand in order to apply the force uniformly.

Most force gauges can measure both tensile and compressive forces in one force axis (often called push-pull force). The force axle can be bi-directionally loaded in modern digital force measuring devices. In the case of mechanical devices, the deformation of the measuring body takes place only in one direction. Therefore, these force gauges must be rotated when changing from tensile force measurement to compressive force measurement. Hydraulic force gauges usually only measure the compressive direction.

Applications of force gauges

Professional use in quality assurance

Manufacturing industries use force gauges mostly to check the product quality and process stability. In doing so, the values for mechanical material properties defined during development and product validation are determined by destructive or non-destructive testing. These may include tensile and breaking strength of materials or compounds, as well as functional forces such as adhesive or holding forces, opening and closing force, frictional force or spring force of mechanical elements or tactile behavior of controls such as buttons and switches.

For the sporadic determination of pressing or holding forces in machines, force measuring devices with a flat, external sensor element are often better suited, since the measuring points between two machine elements are usually confined. To monitor a press-fit or joining operation on hand-operated presses, a force sensor with direct indication between the press ram and the tool can be installed.

In order to characterize material or component properties in more detail, force-displacement diagrams are created, in which case a test stand usually has to be used to determine the measurement data and, in addition to the force measuring device, a time-synchronous clocked displacement sensor is required.

Safety applications of force gauges

Force gauges are also used to regularly check the safety requirements of a technical facility or product. In this area of application, there are a number of different regulations and standards intended to prevent property damage or personal injury. Thus, e.g. opening and closing forces of automatic doors in buildings or vehicles are checked according to accident prevention regulations, the stability of grave stones is determined, or the compliance with the minimum tensile strength of swallowable parts is tested in accordance with the EU Toy Directive.

Force gauges for determining muscle strength

In medical and therapeutic applications, force gauges are used to test muscle power. The aim of this very special force measurement is to check whether therapeutic measures are successful or training programs in competitive sports achieve a corresponding increase in strength.

Typical types of force gauges

Mechanical force gauge

Simple spring scales with Newton display, as mechanical force meter, have the disadvantage that a relatively large deformation (ie extension of the coil spring) is needed to achieve a sufficiently good scale resolution. Thus, a spring balance elongates, for example at a measuring range of 10 N by approx. 100 mm to achieve a scale resolution of 0.1 N The stroke of mechanical force gauges with analogue scale becomes considerably shorter. Here, as with a dial gauge, the compression or elongation of a coil spring is transferred to a pointer in order to increase the resolution at the expense of measurement accuracy.

Schematic: Design of a mechanical force gauge

Hydraulic force gauge

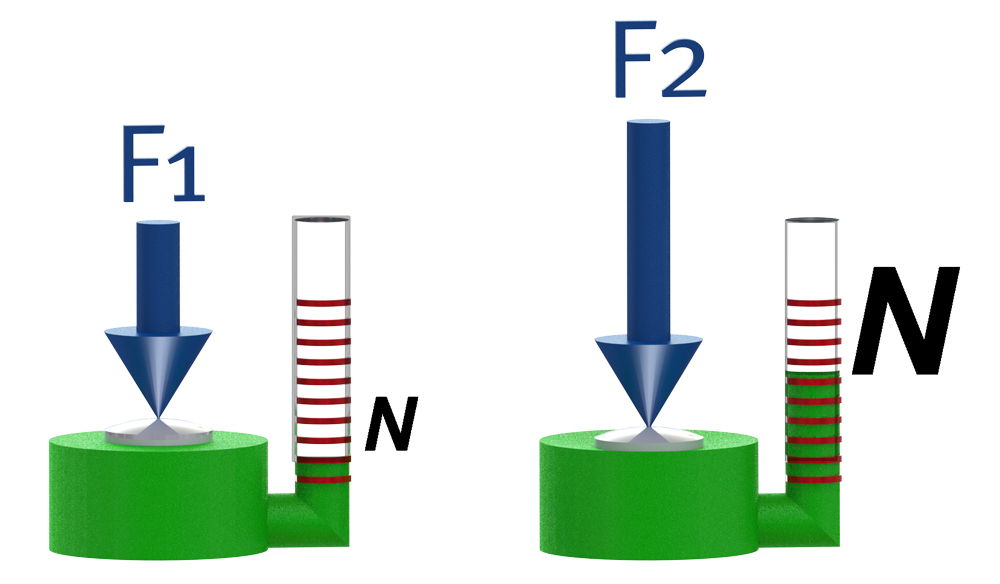

The hydraulic force gauges are often referred to as a load cell or pressure cell due to the typical round design with hollow body and the remote power display. Even in these liquid-filled measuring instruments, a metal membrane is elastically deformed under the action of the force.

The resulting decrease in volume increases the pressure proportionally, or the volume is displaced (see sketch). Force gauges, which are constructed according to this principle, can usually measure only in one effective direction and are usually used to measure very high forces.

Schematic: Hydraulic force gauge or load cell

Digital force gauge

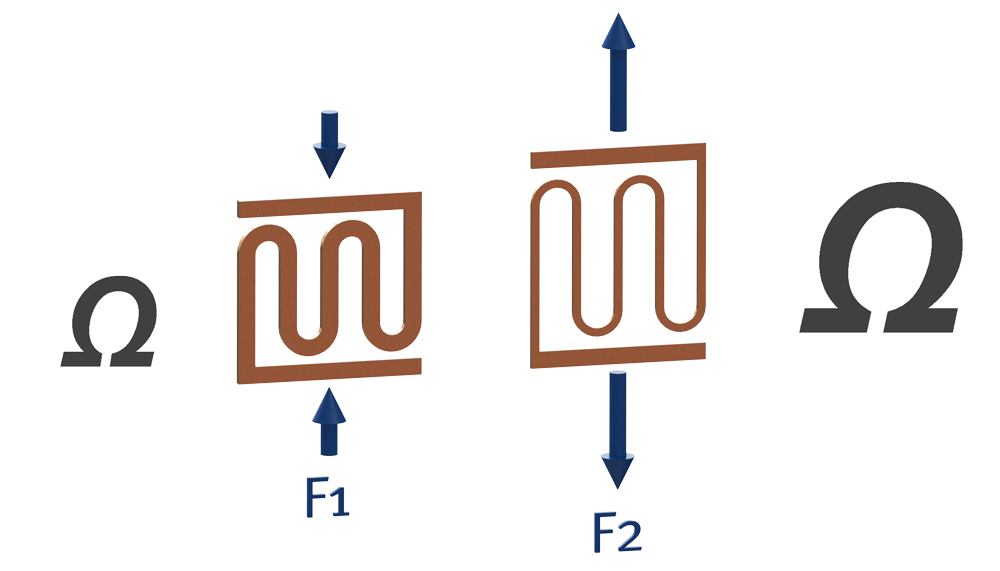

Today, digital force gauges are mostly based on sensors with strain gages (strain gauges). The very small elastic deformations of a sensor body is thereby transferred to a measuring grid, whereby its line cross-section is changed by the strain and / or compression.

This change in cross section causes a change in the electrical resistance, which is captured in the measuring electronics. In principle, Hooke's Law also applies here in a figurative sense, although proportionality is produced by constructive measures on the force transducer and algorithms in electronics.

Schematic: Strain gauges (DMS) for force measurement

The advantage of a digital force meter lies in the very small nominal measuring range of 0.1 to 0.3 mm, with high resolution and accuracy. Parasitic forces from the introduction of force or the position of the force gauge in space are much lower and it is therefore a much better comparability and reproducibility of the results can be achieved.

Special features of the Alluris® force gauges

An outstanding price / performance ratio and the high quality "MADE IN GERMANY" characterize our digital force gauges. Since the founding of the company, we have been continuously expanding our range of force measurement products to provide you with tailor-made solutions and the right force gauge for your measurement needs.

Robust housing

Since only the sensor element and not the housing or the force is to be deformed to determine the force, all Alluris force gauges with integrated measuring cell are built with a one-piece, robust and extremely rigid designed metal housing, at measuring ranges up to 1000 N in die-cast aluminum, at higher forces made of cast steel.

Reliable force measuring technology

Instead of using a simple, cheap load cell, we manufacture our specialized force transducers for FMI-B and FMI-S series digital force gauges. This makes it possible to specially tune the force sensors, the transmitter and the housing for each force measuring range.

The constructive unit of force sensor and surrounding housing in the two FMI-B / S series, leads to 90% reduced damage due to overloading of the measuring cell. Friction-free application of force and the lowest possible mass combined with high flexural stiffness characterize good digital force gauges.

Energy-saving technology

A force gauge of the series Alluris® FMI-S is always ready for operation by the independent energy supply with photovoltaic. Unique to this innovative concept is the extremely low energy requirement of the force sensor itself. The Alluris® FMI-B force gauges also use this innovative energy-saving technology.

As a result, up to 150 hours of operation are achieved without recharging and the LiPo battery retains its full capacity even after years of intensive use of the force meter due to the rare charging processes.

Calibration, service and warranty

Both the digital Alluris force gauges and the mechanical force gauges that complement the distribution program can be calibrated in our ISO 17025 accredited laboratory. If necessary, our calibration service also includes an adjustment and an update to the latest firmware version. For registered devices of the series FMI-B and FMI-S in combination with regular calibration and service we grant a lifelong warranty.

More information about calibration of force gauges can be found on our knowledge site: Force Gauges Calibration

Associated Standards

DAKKS DKD-R 3-3 Calibration of Force Gauges (available free of charge from: Deutsche Akkreditierungsstelle GmbH (DAkkS))

VDI / VDE 2624 2.1 Measuring mechanical quantities - Instructions for calibrating hand-held force measuring devices (available from: Beuth Verlag GmbH)