Torque

Torque (Latin: momentum = motive force) is a physical quantity in mechanics and is denoted by the SI unit newton meter [Nm] and the symbol M. Just like the force, the torque is also a directed or vector quantity.

Effects and designations

Torsional moment

Torsional moment is the moment (force) that is applied to twist a body or component, such as a shaft . It is irrelevant whether the body is at rest or rotating.

Bending moment

The moment required to bend a body.

Output torque

The moment that acts on the output shaft of a prime mover. A prime mover in this sense can also be a transmission.

Drive torque

The moment that acts on the input shaft of a machine element. These machine elements absorb the momentum and convert it into motion. This can be gears, drive axles, wheels or propellers and ship screws.

Tightening or tightening torque

The torque required to tighten a bolted joint or turnbuckle.

Loosening torque / breakaway torque

The moment at which a screw connection or a frictional connection between two cylindrical bodies loosens. If two cylindrical bodies or threads are twisted against each other, a breakaway torque occurs and then a lower sliding friction.

Types of torque measurement

Static torque measurement

Torque can be measured statically on a body when it is held at rest by a counter-torque. In the static state, the moment acting on the body is equal to the counter-moment. If the length of the lever arm is known , this torque can also be recorded by measuring the force. With this procedure, with the greatest possible exclusion of parasitic force influences, static torque sensors can be adjusted and calibrated using masses.

Schematic sketch: Torque shown as a force acting on a lever arm

This principle can be found, for example, in a torque wrench that is used to tighten a screw or nut. The wrench creates a torque to turn the bolt to a predetermined torque threshold and then releases. The (triggering) moment measured by the torque wrench and the counter-torque of the solid body (screw in the threaded hole) are then equal.

The torque required to open screw caps or loosen frictional connections between two cylindrical elements can be measured in the same way.

Dynamic (rotating) torque measurement

If a body is not held still by a counter-torque, the torque generates a rotary motion. The angular acceleration of this rotation is theoretically only limited by the moment of inertia of the body. As a rule, this body is a shaft, which in practice has to be supported, which creates bearing friction and is used to transmit power.

When the power is transmitted via a rotating shaft, the torque that is acting is recorded as a function of the speed. In order to measure the torque, the speed is kept constant with the help of a brake.

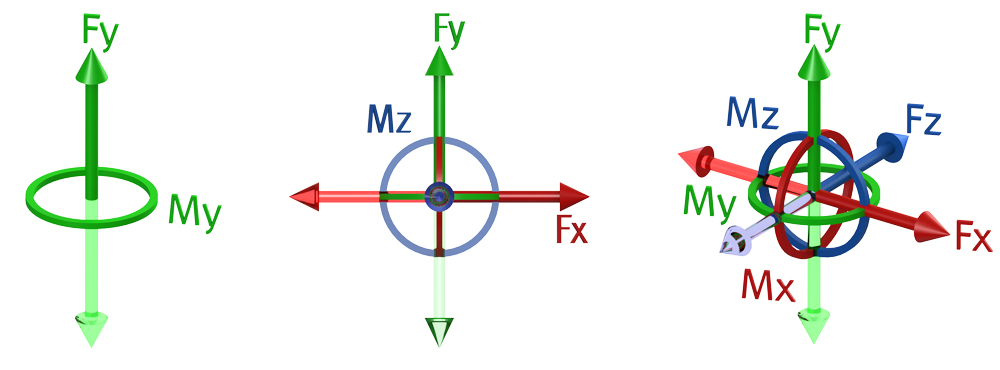

Torque as a vector quantity

Torque is a vector quantity that can act in all directions of an axis of space that is aligned in space. Multi-axis force transducers offer the possibility of evaluating the X, Y and Z components and, if necessary, the respective torque.

Principle sketch: Force as a vector quantity acts in all directions

Torque measuring and testing devices

Torque sensors

Depending on the type of torque measurement, a distinction is made between static and rotating torque sensors. The static torque sensors based on strain gages (DMS = strain gauges) measure the deformation of a torsion body. The basic principle corresponds to that of force transducers. (see also: force measurement ) Most rotating torque sensors also work on a strain gage basis and transmit the signals from the rotating shaft via slip rings.

Torque wrenches and screwdrivers

Depending on the design, torque wrenches and torque screwdrivers are either equipped with a torque indicator or a torque release. Some of the displaying devices can record a limit value and signal it optically or acoustically. Triggering torque wrenches provide tactile feedback when the set torque value is exceeded. Torque screwdrivers do not allow higher torques than the set ones and "spin through".

Torque measuring devices for static and quasi-static applications

In order to measure the torsion torque, tightening torque, loosening torque or breakaway torque on small components, screw caps in the packaging industry or cylindrical bodies that can be adjusted relative to one another (e.g. camera lenses), table-top devices for torque measurement are used in which the torque is transmitted to a built-in strain gauge sensor.

torque testers

In order to verify and calibrate the switching point or the display of torque tools , torque testers are used, which represent a static counter-torque instead of the screw connection. The testing devices are used in particular in areas of assembly where the correct tightening torque of a connection is decisive for the service life and quality of the end product. As a rule, these tools are calibrated at least once a year in order to ensure that the display or trigger unit Nm can be traced back to the national torque standards of the PTB (Physikalisch-Technische Bundesanstalt).

As an alternative to this, rotating speed sensors can also be installed between the screwing tool and the screw connection and connected to an evaluation unit in order to check the switch-off torque of a motorized screwing tool.

Normative references

DIN EN ISO 6789:2017 Screwdriving tools - Hand-operated torque tools - Requirements and test methods for type testing, acceptance testing and the recalibration method (to be obtained from: Beuth Verlag AG )

DAkkS-DKD-R 3-8 - Static calibration of calibration devices for torque wrenches (to be obtained free of charge from: PTB Physical Technical Federal Institute - Publications )

VDI/VDE 2646 - Torque measuring devices - Minimum requirements for calibration (to be obtained from: Beuth Verlag AG )